We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

Jewellery of a trunk

Jewellery from a trunk

As these trunks have survived the passage of time, it is not uncommon to find parts missing, missing or damaged during a journey. A broken lock, a broken handle or simply a missing nail; for each of these missing parts, we have to find the closest replacement to the original part.

Once the trunk is complete, a major cleaning operation is carried out on the entire piece of

jewellery, with specific methods depending on the materials used.

Locks and metal parts are generally made of brass, steel, copper and aluminium.

Handles and borders can be made of vegetable leather, pigskin, brass, aluminium, steel or

parchment, while the battens (wooden slats) are mainly made of beech (strong and resistant

wood).

Cleaning brass

In the 19th and 20th centuries, brass was the metal most used by trunk makers. An alloy composed of copper and zinc, it is very resistant and can be worked quite easily both hot and cold. It was mainly used to make locks, hinged handles and angle irons. It is brighter than bronze and is very strong.

The cleaning of brass parts is an important part of the restoration of a trunk. These parts need to be cleaned, with the level of oxidation depending on where the luggage was stored. The more the trunk has been exposed to humidity, the more likely it is that the brass will be attacked by oxidation (it is the contact between the brass and oxygen that creates this corrosion on the part).

Today, the brass used by Louis Vuitton is subjected to numerous resistance tests and its composition is modified to better withstand new climatic conditions. During these tests, the parts are exposed to salt spray or synthetic sweat in order to analyse and improve their resistance to natural corrosion.

The brass nails

The nails and rivets used to hold the jewellery in a trunk were usually made of two materials, with a brass head and a steel shaft. This combination preserved the strength of steel and the shine of brass.

Originally, the curvature of the nails prevented friction between two trunks stacked in a wagon. Louis Vuitton is said to have started using these fasteners in the 1860s, which quickly became an integral part of the luxury trunk. To distinguish himself from the competition, George Vuitton had the company's name engraved on the brass head of each of the nails, making up a Louis Vuitton trunk.

Because these nails are marked, they are very difficult to find today. Therefore, we need to preserve and restore all the rivets and nails present on a Louis Vuitton trunk, which cannot be saved. We are actively looking for Louis Vuitton luggage in any condition.

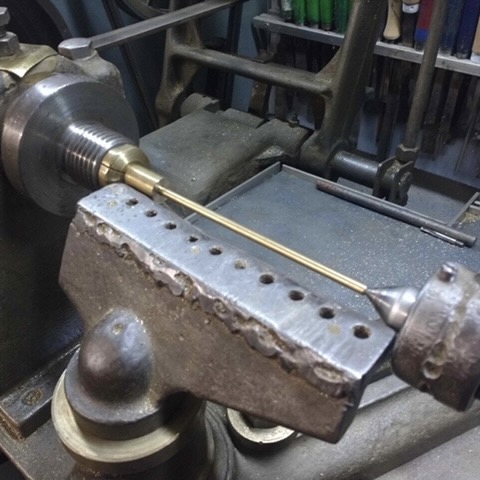

Manufacture of specific parts : The brass

The bronze craftsman adapts according to the type of request, with the possibility of creating a mould or directly sculpting the brass. On the left is the creation of a brass handle for a small Hermes jewellery box from the 1950s covered in Doblis calfskin. The handle was sculpted and then gold plated to restore its original appearance.

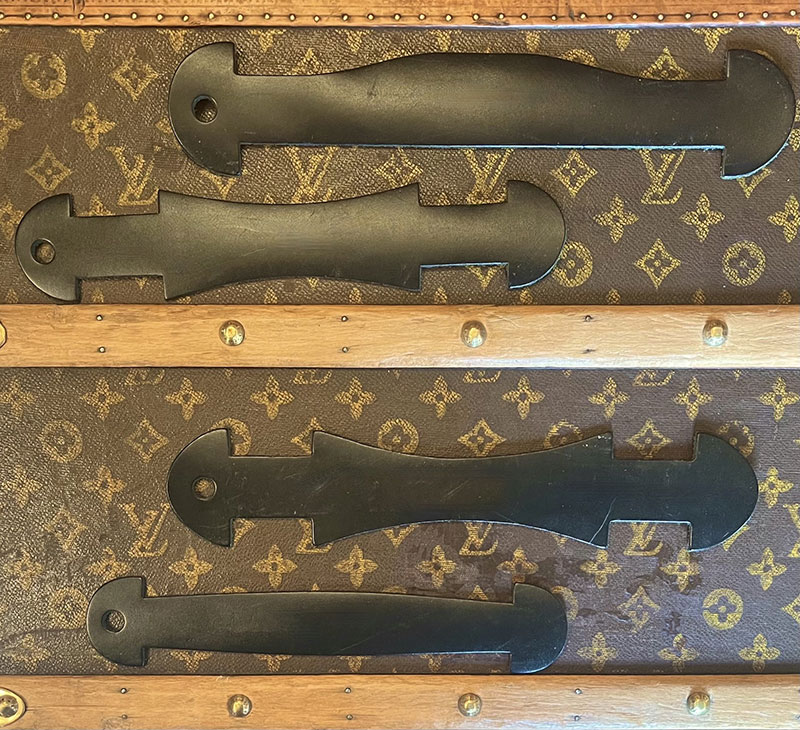

The leather Man

The leather craftsman also has many constraints when restoring the leather parts of a trunk. He has to find the patina of time and the manufacturing methods of the time, so as not to alter the appearance of the luggage. Special threads, wide nets, unique markings and often unknown techniques make the task particularly complex. Together we must constantly learn and adapt to each new project.